Changing the Way the World Makes Brick

Then and Now – Maintaining a Legacy

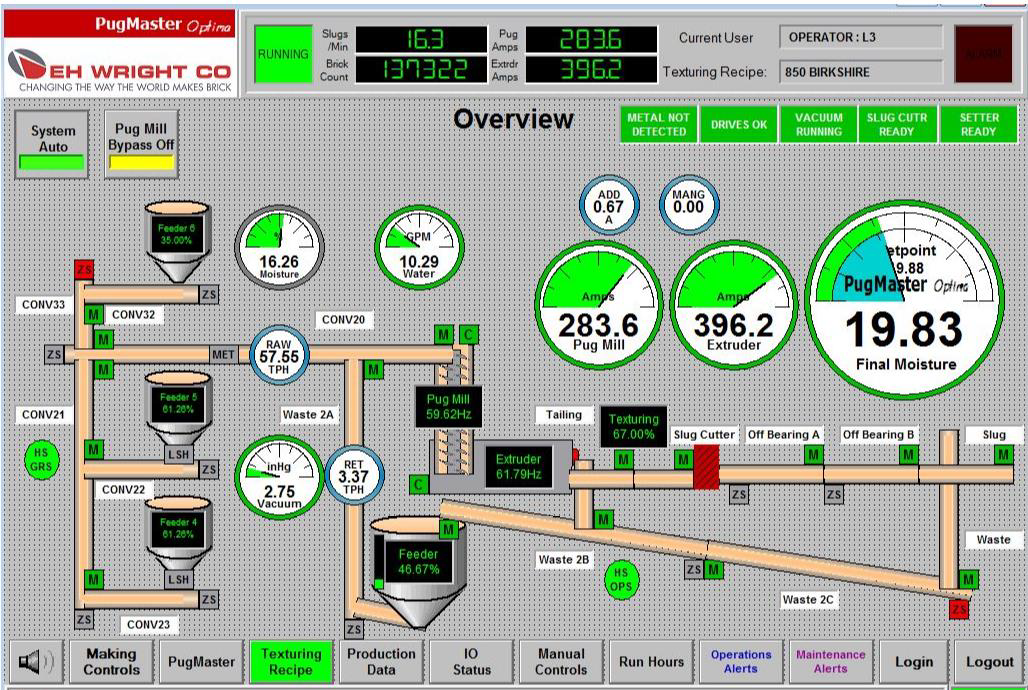

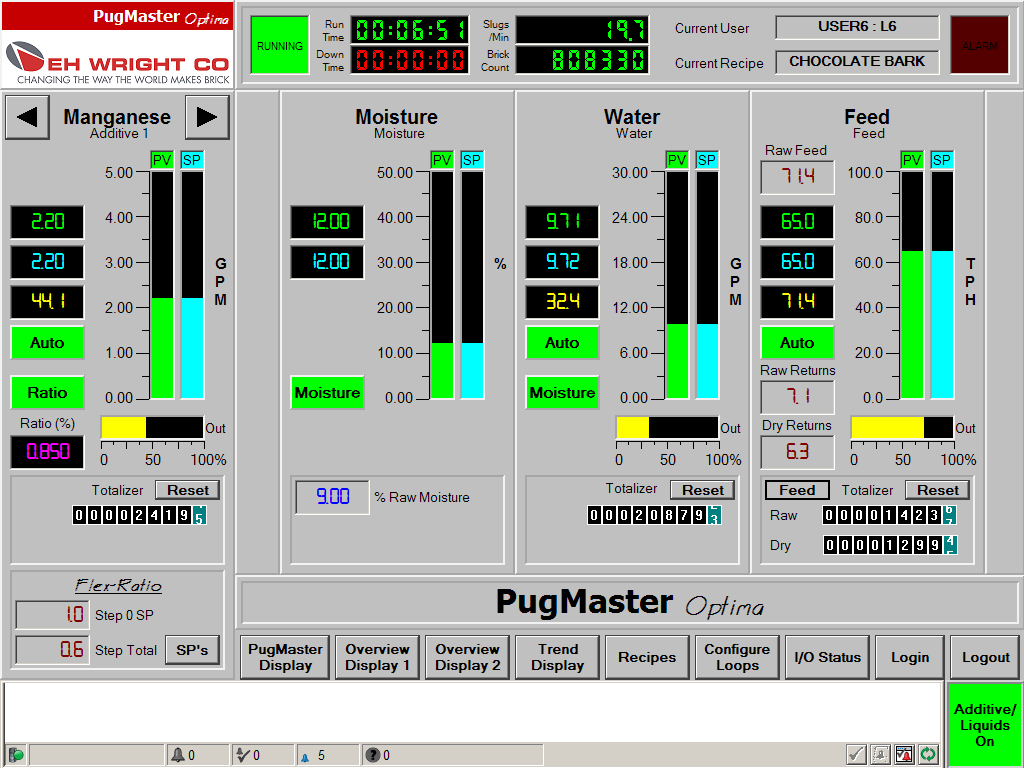

EH Wright Company provides automation solutions designed for manufacturing companies whose process contains raw materials having varying moisture contents. Our US patented PugMaster application originated in 1994 for the Brick and Tile Clay Extrusion Industry and EH Wright CO. has maintained our status as the worldwide leader in clay extrusion column control. The PugMaster System architecture is designed around “Feed-Forward” control which requires a material Belt-Scale and material Moisture Sensor to obtain pre-extrusion data. The plant extrusion operator enters a desired “Final Column Moisture” set-point and the control algorithm dynamically calculates the amount of water (or other) to be applied into the PugMill or mixer.

Our Products

BatchMaster H2O

Water Batching Controller

Controlling the additive flow is only a portion of the overall scope of applying liquid additives into the extrusion process. Consistent, repeatable mixing of materials is as critical to the product quality. If the concentration of the additive is not consistent, the result will not be either.

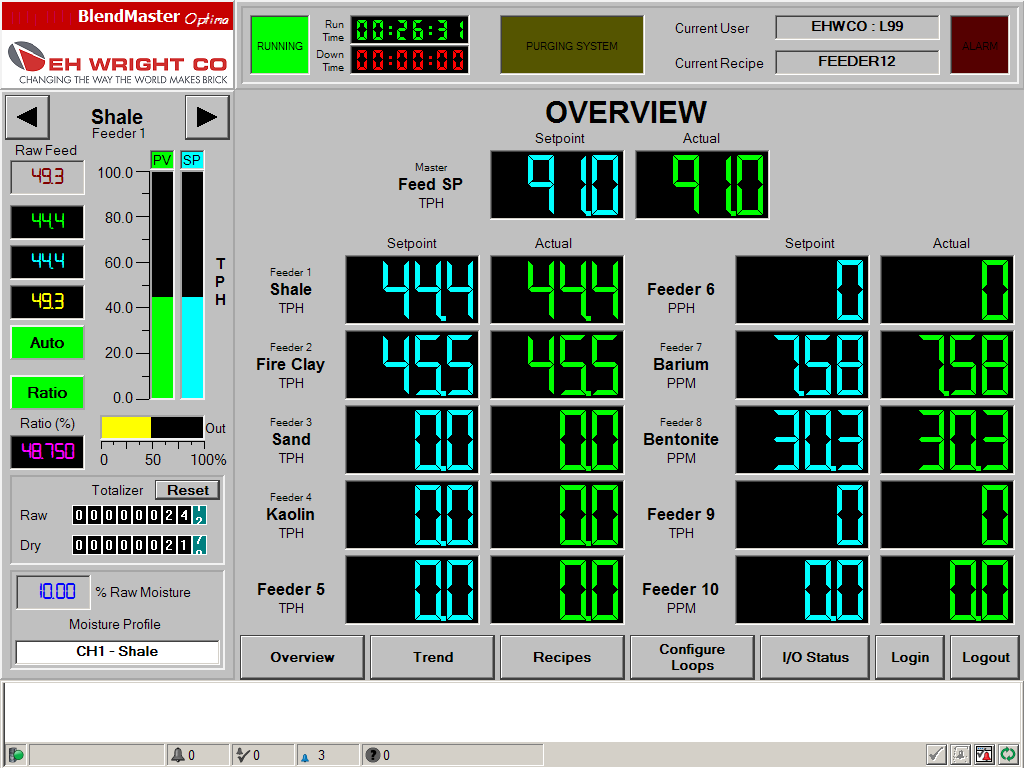

PugMaster Optima

A culmination of years of experience in the Brick Industry and state of the art, globally accessible automation technology.

EH Wright Co has teamed with Rockwell Automation to provide the most technologically sound and globally supportable control system in the industry for the extrusion process.